When Ronald Liebmann from the Eisenach facility is putting together the materials cart for the dashboard of an ADAM, he always selects exactly the right part, even though there are so many different parts to choose from. Similarly, Michael Müller and Willi Entenmann at the engine assembly facility in Kaiserslautern are always confident that they are using precisely the correct screw or bearing shell. That’s because both of these plants – located in Thuringia and Rhineland-Palatine, respectively – use smart technology to help prevent errors in realtime. Smart glasses, trackers worn on the hand, and smartwatches are just some of the intelligent assistants that define this new age of industrial production, the age of the ‘smart factory.’

Test scenarios graduate

from the laboratory.

The concept refers to a production environment where manufacturing facilities can largely organize themselves without the need for human intervention. The course is being set by the team at the ITEZ in Rüsselsheim, Germany, in the area of ‘Advanced Manufacturing Technologies’ (AMT) led by Dr. Petra Krammer. They are working hand in hand with the colleagues from the fields of supply chain and manufacturing IT. “There is still a long way to go until we reach the full Smart Factory level, in which machines, people, tools and resources network and communicate seamlessly. However, we try to implement smart technologies in our plants, such as the cyber physical systems, in order to optimize operation in real-time“, explains Krammer.

Smart assistant The smart glasses provide sequencers in Eisenach information about which parts must be removed from which boxes.

Essential aid There are 450 parts in the ADAM’s dashboard alone.

At the AMT laboratories, field technology specialist Dr. Benjamin Kuhrke and his team are working to develop intelligent assistance systems. “When we put an activity tracker to the wrist that transmits data to the smartphone via Bluetooth, or when we get real-time data on the current traffic or weather conditions on the display, then we naturally use smart helpers, which have become integral parts of our daily private life“, explains Kuhrke. His team is currently collaborating with a number of departments of the ITEZ to explore the ways in which this technology can be applied in all of the different areas of the plants. Some of the applications tested at this laboratory have already graduated from the testing phase and are currently in use today.

Fault prevention in real time The part number matches the specified item. The employee is provided with the necessary information on the display of the smart glasses.

Order picking in Eisenach

We’re at the set-part-system (SPS) station cockpit at the Opel plant in Eisenach. This is where the 450 parts of the ADAM and Corsa dashboards are sequenced, collected and organized for line assembly. The late shift has just begun. Twenty-year plant veteran Ronald Liebmann navigates the materials cart through the station, past a dozen boxes of materials. He stops, removes a part, places it on the rack, and then moves on. Liebmann is wearing a scanner on the back of his hand and a pair of smart glasses. Intelligent assistant systems such as hand scanners, tablets, smart watches, and smart glasses made their debut at the set part system station for dashboard and side window assembly in mid-January. Liebmann uses his hand scanner to scan the order code. The name and coding of the required item are then displayed in the right-hand lens of his smart glasses. The number of the next item on the list appears in yellow on the display. A green checkmark indicates that the order is complete. Ronald Liebmann elected to work with the smart glasses because, according to him, “They’re great to work with and you can keep your hands free.” Employees are also free to select a smartwatch or a tablet.

The team in Rüsselsheim implemented the new technology with the help of a team from Eisenach led by Frank Schäfer, Assistant Manager Supply Chain, and Thomas Döring from Core Team Supply Chain. Today, around 2,300 different parts are routed to their destinations using smart assistant devices. That means that around 30 percent of all parts are currently being sequenced with the help of quality assurance systems – and those numbers are on the rise.

“The greatest advantage of the assistance systems is that there are virtually no mistakes any more, which reduces rework and relieves the employees of their work.“

– Dr. Benjamin Kuhrke –

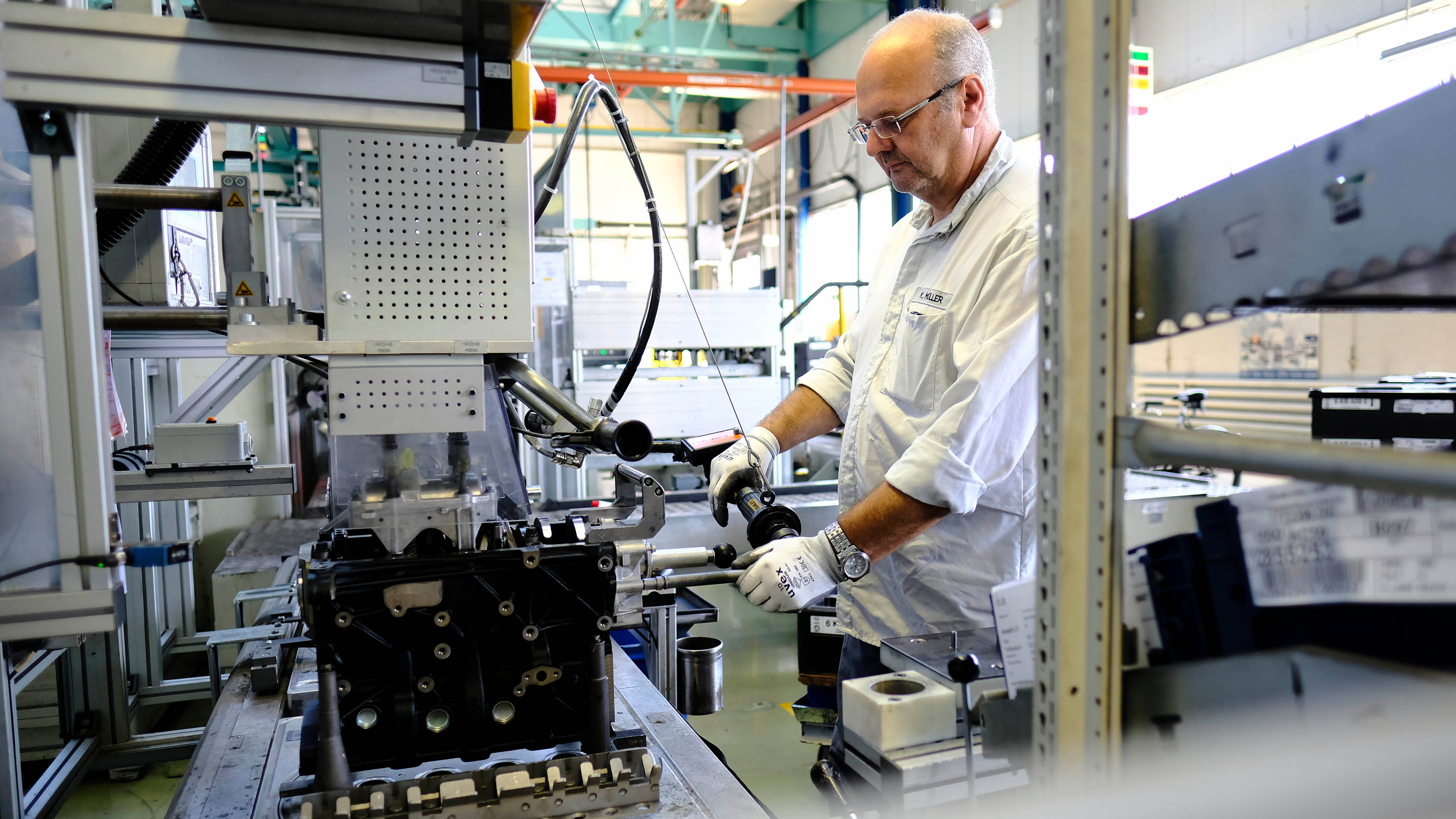

Oil pump assembly In Kaiserslautern, Michael Müller works with a tool that doubles as an assistant.

How does it work? The monitor shows which screw needs to be tightened next (left), and the tracker on the handling unit ensures that no other screw can be tightened (right).

“When I try to tighten the wrong screw, the screwdriver locks until I use it on the right one.”

– Michael Müller –

Intelligent tools at the Opel plant in Kaiserslautern

Michael Müller has worked in engine assembly at the Opel plant in Kaiserslautern, Germany for 12 years. He is now a team leader. The way he works with his tools has long since entered his bloodstream. But never before had he held a screwdriver like the one he has used over the past few weeks to work on an oil pump. Not only does it handle flawlessly, but it even seems to have a mind of its own: “When I try to tighten the wrong screw, the screwdriver locks until I use it on the right one.” That translates into fault prevention in real time. The technology that makes it possible is the ‘infrared tracker’ attached to the screwdriver. An infrared camera records all the tool’s movements and monitors the procedure to ensure it is done correctly. Müller keeps track of everything right at his workstation, thanks to a monitor that depicts the next step in the procedure and evaluates the previous step. The setup not only prevents mistakes from being made, but also guarantees optimum transparency.

Cylinder head assembly Willi Entenmann is wearing a motion tracker on the back of his hand. This device monitors his work as he installs the correct bearing shell. The fascinating thing about it: The system works so precisely that it is possible to reliably detect the joint patches that are only a few centimeters away from each other. This is the first time such a tracker has been placed on an employee’s hand. Used in this way, his fingers act as sensors for the device.

In preparation In addition to the current pilot projects, the AMT team is working on further ideas in the field of smart worker assistance. In Eisenach Frank Schäfer demonstrates a tracker, which can be attached directly to the welding tape. The tracker will help to monitor the extraction of side windows in the future.

The AMT team is spearheading other new ideas.

Other application examples developed by the AMT team can be described as tablet-based solutions, which enable real objects to be superimposed with virtual objects and thus be compared for quality purposes. The key word here is augmented reality. When placed on the nose as data glasses, the fulfill another mission and support new employees during the training or maintenance work in the repair of machines. These and other ideas are being developed by the AMT experiment lab.

The team from Advanced Manufacturing Technologies and the colleagues from Eisenach (from left) Frank Bartnik (Manufacturing IT), Sebastian Wörlein (KIS student, AMT), Frank Walper (Manufacturing IT), Annett Kästner (Eisenach), Frank Schäfer (Eisenach), Dr. Benjamin Kuhrke (AMT), Thomas Döring (Eisenach), Thomas Bradsch (Eisenach) und Enrico Theeg (Eisenach).

February 2017