- Insignia-Werkschau: Für das neue Flaggschiff hat das Opel-Marketing eines der aufwendigsten Shootings organisiert, die das Stammwerk in Rüsselsheim je gesehen hat.

Start of sales

From now on, customers can order the Opel flagship as a Grand Sport limousine, Sports Tourer estate and particularly dynamic GSi.

Flash units extend far up towards the ceiling, cables are strewn across the concrete floor, and a camera and the laptop it is attached to are perched on a heavy-duty tripod. Assemble line workers who just completed their shift are looking over curiously at six people dressed in orange vests who are setting up their equipment at the end of the production line. It is now day three of the most complex photo shoot ever seen at the main Opel production facility in Rüsselsheim. For an entire week in December, the crew photographed the new Insignia where it is made: in the main production facility, at the end of the assembly line, in the old K48 production hall, outside between buildings, in the Design Center, and at the Dudenhofen test center.

![]()

The perfect backdrop: The new Insignia shows off some of its innovative features as it rolls off the line. To open the sensor-controlled tailgate, For example, all you need to do is click your foot. ↑

Is the lighting just right? The photography crew checks the preliminary results while still on set. →

Perfection to the smallest detail: Here’s a look at the new flagship model in the final image.

↓

![]()

“We didn’t just want to showcase the new flagship model; we also wanted to present the plant where the Insignia is produced.”

Tobias A. Gubitz

Director Brand Strategy

Photo shoots for new models tend to be set in sunny South Africa or on a winding road on America’s West Coast. But not usually in cold, wet weather. Then why was the decision made to do the photo shoot at this location? Tobias A. Gubitz, Director Brand Strategy and Marketing Communications, has the answer: “We wanted the photos to do more than just showcase the new flagship model; we also wanted to present the plant where the Insignia is produced.” Generally speaking, customers are not given a glimpse inside the plant and into all that goes on there. Gubitz: “We want to show that we are proud of our products and our main production facility in Rüsselsheim.”

Perfection Cannot be Rushed

A lot of planning went into the photoshoot in Rüsselsheim. It took the well-organized team nearly two months to complete their work. “And that’s actually quite fast,” says Ralph Hillert, who owns Frankfurt-based production company mainworks. To pull off a project of this complexity, you need to plan everything in great deal. It all begins with the concept phase, where decisions are made on what will be shown in the photos. When this step is complete, planning gets underway with advanced scouting. This entails selecting possible locations and motifs. Everyone involved at the plant was brought on board. Next, permits had to be issued before the photo shoot could proceed. After the shoot was over, the photos were sent to post-production, where a team of five specialists spent an entire week on just two images.

![]()

← Opel headquarters in December: The crew prepares for an outside shoot in building K171.

↓ Playing a supporting role: The Opel Astra V8 Coupé from the Opel Classic workshop is moved into position.

![]()

A true work of art: The Grand Sport and Sports Tourer versions of the Insignia parked in front of the production hall, with an Opel Astra V8 Coupé in the background.

↓

![]()

“I’ve rarely experienced such great teamwork. You get the sense that Opel has a very special culture. Nothing is impossible here.”

Moritz Duesterberg

Production manager on the Insignia shoot

![]()

The main phase of the project was the multi-day photo shoot at the plant. Since the shoot was taking place in Hesse – not South Africa – there was always the chance of rain. And if it did rain, that would throw a wrench in the planning. “You need strong nerves for a project like this,” says Moritz Duesterberg, production manager on the Insignia shoot. Luckily, the northern German is not easily rattled, even when things got hectic and he had to improvise because a road in front of the plant was blocked off, making it necessary to find a new place to unload deliveries.

Working Back to Front

It’s worth noting that the Insignia was not even there at many of the shoots. That’s because the new model had to be kept under wraps prior to its official unveiling to prevent photos from being leaked. For that reason, a number of backplates were made first. The Insignia was not added to the photos until post-production. The photo backplates were taken with special medium-format cameras. Thanks to the high-resolutions possible with these cameras, the entire image is crystal clear from top to bottom, with no details left out. And when an Insignia was in front of the camera at the photo shoot at the end of the production line or in building K171, this was for one single purpose: to capture the light reflected off of the paint and later add this element to the computer-generated 3D model of the Insignia.

“Backplates“ are a common stylistic device in modern advertising photography. The large-format overview photos of landscapes, streets or cities are taken with special cameras, such as medium format cameras, and impress with their high resolution and colour depth. They serve as a background for isolated objects that are subsequently placed on the computer.

![]()

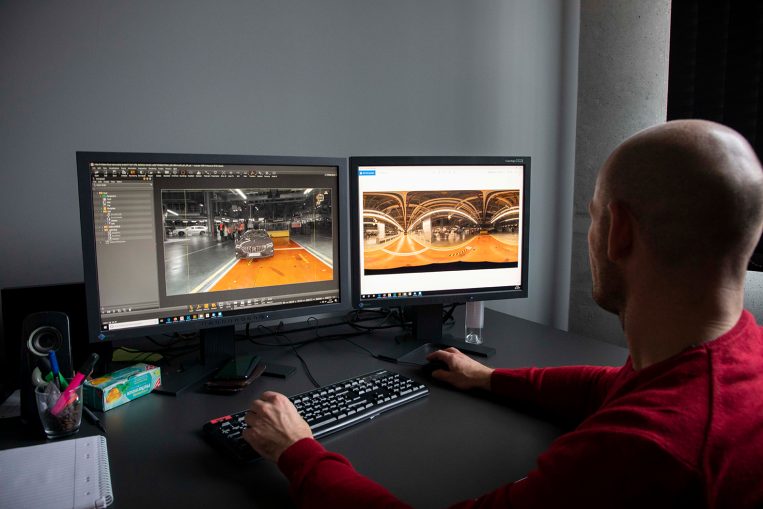

↑ Post-production on the computer: The wide mangle photo on the right monitor helps the editor to place reflections on the surface of the vehicle.

← Color check: Ralph Hillert from the production company mainworks makes sure that the paint color is just right.

↓ Small things matter: Proofs provide a preview of how the printed photos will look. Final adjustments are made to the color, sharpness, and brightness levels.

![]()

Video: This is how the

Insignia comes on photo →

![]()

“We’re proud of our flagship model. Why shouldn’t we give our customers an inside look at our main plant?“

Michael Lewald

Plant Manager Rüsselsheim

Duesterberg is happy to report that all in all, the photo shoot went off more or less without a hitch. According to the production manager, “That was all thanks to great work of the plant staff.” “I’ve rarely experienced such great teamwork. You get the sense that Opel has a very special culture. Nothing is impossible here. That made our work easier in many ways.”

Inside Look Into The Main Plant

Michael Lewald, Plant Manager at the main production facility in Rüsselsheim, already knew this. “We’ve learned to work together as a team. You can always count on your co-workers,” says Lewald. He’s really excited that the new photos of the Insignia were taken at the Opel facility. He then goes on to say: “We’re proud of our flagship model. Why shouldn’t we give our customers an inside look at our main facility? Especially when you consider that we have one of the world’s most modern car-making plants.”

![]()

Other themes: The Insignia

on show at Opel headquarters … ↓

- Mit passender Dachbox auf dem Gelände des Stammwerks

- Als Blickfang im N10-Trakt des Designzentrums

- In beiden Karosserie-Varianten mit Blick auf die Fertig- und Endmontage

- Mit edlem Interior und Blick auf das Adam Opel Haus

- Stilvoll in den Fertigungshallen

- Dynamisch im Hallenkomplex K48

- Kraftvoll im Testzentrum Dudenhofen

![]()

There are several places where you can find the final photos of the new Insignia from our main production facility. For example, you can check out the new catalogue or go to opel.de. The pictures came out great. They show the flagship model where it is designed and built by dedicated staff. The photos fully reflect the brand values of the carmaker with the lightning bolt: German, exciting, and approachable.

![]()

↑ A fascinating look behind the scenes: The Insignia leaves the acoustics laboratory, where engineers worked to achieve the perfect noise levels during the development phase.

March 2020