Well-rounded materials: These textiles could have been used to make driver airbags, but they became stylish Studio Knuy cushion covers instead.

——

“Our goal isn’t to mass-produce products. We want to create sophisticated, quality furniture.”

——

The room temperature might be low, but the spirits in here are running high. This workshop, located in a back courtyard in Aschaffenburg, Germany, is alive with a sense of possibility: This is where two young creatives bring their dreams to life. The workshop’s lofty, single-glazed windows are full of cracks – they have been mended at many points and covered with graffiti. Snatches of music and conversation drift over from next door. “This workshop belongs to friends of ours, so we’re only using it temporarily,” explains Anne-Sophie Schwarz (27), as Christine Herold (28) pulls up some plastic chairs. This is where these trained designers develop their ideas and prototypes. Schwarz and Herold trade in upcycling, breathing new life into used or purportedly useless items. They use an unexpected material to make their stylish seats: airbags.

——

“We had the idea to make something out of car parts.”

——

Tools of the trade: The designers make their prototypes with traditional means.

Hunting for Treasure at the Junkyard

Herold and Schwarz took part in a textile upcycling competition held as part of a trade fair in early 2015. They had already engaged with this kind of design during their Industrial Design studies at the Darmstadt University of Applied Sciences, from which they both graduated in 2014. “We had the idea to make something out of car parts,” Schwarz explains. So they went off to the junkyard looking for treasure. “We were immediately intrigued by some airbag material that we found hanging out of a steering wheel.”

They brought quite the interesting haul back home from the junkyard. Playing around with their finds, they created a stool using old vehicle parts. It consisted of two tractor steering wheels screwed together – the one on top was covered in seatbelts and crowned with an airbag repurposed as a cushion. The final product was striking. “We got a lot of positive feedback and recognition for that stool,” says Herold. Emboldened by their success, she and Schwarz worked to fully flesh out their design concept. They went freelance and named their project Studio Knuy. Incidentally, ‘Knuy’ isn’t a cute name lifted from some Swedish furniture store – the designers came up with it themselves. Herold explains: “It comes from the word ‘junkyard.’ When you spell ‘junk’ backwards and add the first letter of ‘yard,’ you get ‘knuy.’”

Custom furniture design: Cushions and cushion covers in various shapes and sizes come to life on the Knuy workbench.

The complete collection: The designers showcase their creations. The steering wheel stool in the front left was their first piece.

→ Studio Knuy

Procuring Materials Was a Dangerous Endeavor

The designers quickly encountered their first obstacle: procuring materials. “The steering wheels were very hard to find. We had to bid on them individually online,” says Herold. Finding airbags posed an even greater challenge. Airbags contain an explosive material to ensure that they inflate within milliseconds in the event of an accident; because of this, they can only be disassembled by specially trained personnel. “We had to detonate the airbags and wash them multiple times in order to remove chemical residue,” explains Herold. This was a dangerous, time-consuming, expensive, and environmentally unfriendly process. Studio Knuy’s business concept was in jeopardy – but hitting the brakes was out of the question.

——

“My contact immediately filled up a truck with a load of factory rejects and brought it over.”

Uwe Ruster

Lead Engineer Recycled/Sustainable Materials

——

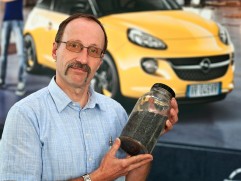

“We came across Opel during our research and got Uwe Ruster on the phone,” says Schwarz. This marked a turning point. Ruster, who works as Lead Engineer Recycled/Sustainable Materials at Opel’s site in Rüsselsheim, Germany, liked the idea of repurposing car parts as furniture, got along well with the designers, and provided them with a great connection. “We work together with companies that sell and process airbag material that’s been marked as defective during the production stage,” explains Ruster. He introduced the designers to his contact at an airbag supplier: “All that cost me was a phone call, but it really helped them out.” The supplier was happy to provide assistance. Ruster recounts that “My contact immediately filled up a truck with a load of factory rejects and brought it over.”

Anne-Sophie Schwarz struck gold at the junkyard: “We were immediately intrigued by the airbag material.”

Christine Herold is grateful for Uwe Ruster’s suggestion to ask for factory rejects: “That led us to a goldmine!”

Breathing New Life into Would-be Airbags

“Uwe Ruster’s contact and the material supplies were a real goldmine for us,” says Herold. These supplies had been declared unfit for safety standards due to minor structural or sewing defects. However, these factory rejects are still perfectly suitable for making trendy cushion covers. “Their pastel colors and contrasting stitching are a great fit for our design concept,” says Schwarz, reaching for cushion covers in light blue, gray, and pink. The airbag textiles came straight from the factory – they didn’t need to be sourced from junkyards, disassembled, detonated, and cleaned. These materials are perfect for repurposing: They are high in quality, durable, easy to process, water-repellent, washable, dyeable, and feel pleasant to the touch. In Herold and Schwarz’s capable hands, these would-be airbags are transformed into stylish cushion covers.

Opel treasures objects with a past

Uwe Ruster, Lead Engineer Recycled/Sustainable Materials

Opel started developing its clever recycling ideas all the way back in 1990, in order to increase the proportion of materials made from recycled scrap in new vehicles. As such, the lightning-bolt brand is leading the way in the automotive industry in terms of using recycled materials. Recycling has become a hot topic: As of 2015, 95 percent of a vehicle’s average weight must be comprised of reusable or recyclable materials, as dictated by the E.U.’s End of Life Vehicles Directive (2000/53/EC).

This directive calls for reducing waste and expanding recycling efforts. Many plastic recyclates, or products of recycling processes, are used in automotive production. To make these recyclates, scrap or residual materials are broken down into the smallest possible components and cleaned before being reused as raw materials. Once they have been reprocessed, these recyclates can be combined in various mixtures (depending on the intended use) in order to create new components. Suppliers often use processing pellets as a raw material to produce new components via plastic injection molding processes – in strict compliance with regulations, of course. Moreover, using processing pellets consumes less energy than it would to use new materials; as such, these reused materials directly benefit the environment and CO2 levels.

Since recyclates are subjected to more stringent standards and requirements than new materials are, they are very high in quality. Thanks to their intelligent design, components made from reused materials can actually boast even better material properties than ones made from new materials do. Recyclates are used in all applications where it makes sense to do so from a technical perspective. For example, Opel has incorporated over 220 recyclates into its current models.

The new Astra alone contains over 200 recyclate components. The water deflector between the windshield and hood had a past life, as did the bumper mountings and the intake manifold. Opel plants use up to 45,000 metric tons of recyclates annually in automotive production.

Studio Knuy was only able to deliver individual pieces in the beginning; today, the start-up can handle more at once. “We even get factory reject material by the meter, in rolls,” Schwarz excitedly recounts. She and Herold are now working with an airbag supplier based near Frankfurt, Germany. The start-up has also begun a cooperation with the Frankfurter Verein für soziale Heimstätten e.V. (Frankfurt Association for Social Homes), an organization that works with the handicapped and mentally ill. The organization offers jobs sewing Studio Knuy cushions in a workshop as a rehabilitative service. “But our goal isn’t to mass-produce products,” Herold clarifies. “We want to create sophisticated, quality furniture.”

Networking and Making Strides

According to Schwarz, she and her business partner still aren’t living off of their project: “But we’re doing well. We’re now able to accommodate larger orders and can plan with a greater degree of certainty.” At the moment, she and Herold are spending less time in the workshop and more time breaking new ground as a company. “We’re meeting with potential customers and business partners, and working on brochures and pricing,” says Schwarz. “They didn’t teach us how to do that in college! It’s exciting and fun.”

At the sewing table: Anne-Sophie Schwarz puts the finishing touches on a cushion cover.

Studio Knuy’s latest products are modular lounge furniture pieces made from compressed wood scrap. They consist of so-called ESB wooden panels, which are extremely high in strength. Once they have been processed, varnished, and combined with cushions made from airbag textiles, these panels are transformed into smart, flexible furniture. Herold and Schwarz are now aiming to have their furniture featured in interior design catalogs. They say, “We’d love to take on orders from bars, lounges, and trade fair booths!” Those kinds of orders are not far out of reach – their airbag cushions will soon be featured in the Adam Opel Building as well as at automotive trade fairs.