On this Wednesday morning, a well-rehearsed cycle is in progress at the M55 in Rüsselsheim: a truck pulls up and employees start unloading special wooden crates that contain dismantled battery packages. The e-drives come from all over Europe. In the cases when dealers from Portugal to Poland are not able to provide further help, the lithium-ion batteries are delivered to the “Battery Refurbishment Center” at Opel headquarters – and repaired here as needed. Before the truck returns to the French interim warehouse in Vesoul, it is reloaded with special crates containing battery units that have already been refurbished. With this circuit of replacement batteries, e-car customers receive the fastest possible service.

“The batteries are robust, the failure rate is very low.”

In addition to the Ampera and Ampera-e, the colleagues in M55 take care of the drives for all models on the eCMP platform, such as the Opel Corsa-e and Peugeot e-208. Markus Grassmuck is the production manager and he takes a look at the delivery. There are eight crates. The maximum. There have never been more. Because: “The batteries are robust, the overall failure rate is very low.” Last year, the team at the Center dealt with about one hundred defects. “And that in an e-car fleet that is up to ten years old,” Grassmuck emphasises.

The Battery Center is well prepared:

After all, more people are currently opting

for an electric car than ever before.

E-cars are gaining ground. More people than ever before are opting for electric drive. Take the Corsa, for example: in Germany, one in three private customers buys the electric version. The Mokka-e is taking the market by storm, followed by the Combo-e and Vivaro-e – Opel’s electric offensive is in full swing. Accordingly, the Battery Center at Opel’s headquarters has now been significantly expanded and modernised. Currently, half a dozen colleagues work in the Opel Special Vehicles (OSV) hall, and by the end of the year this number is expected to double.

High-voltage

experts at work

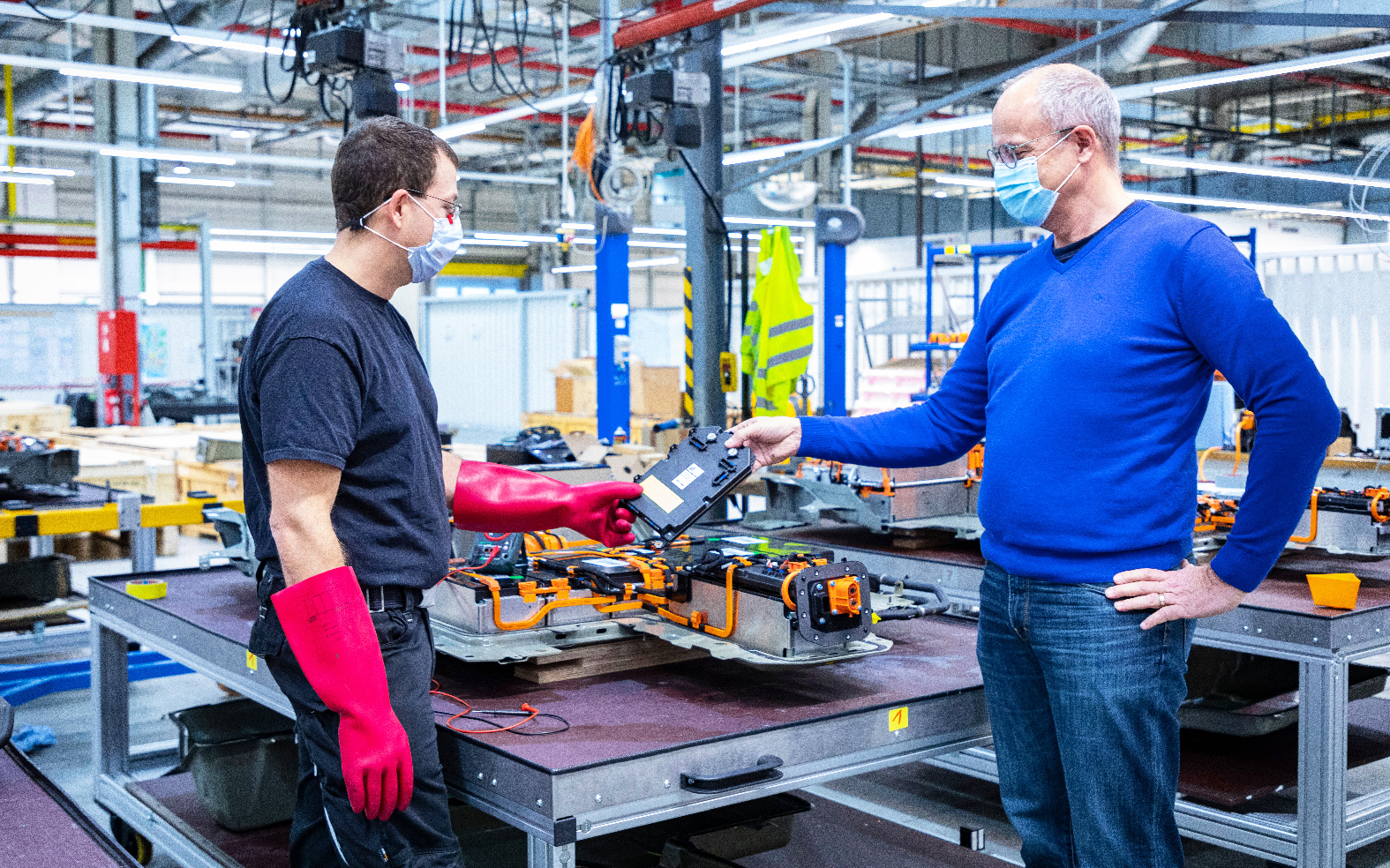

The hall is divided into individual shielded cells. A battery unit is already in one of them. It comes from an Ampera. Everything is clean, tidy, the tools are neatly lined up. The scene is reminiscent of an operating theatre, and not only because of the face masks the team wears to protect them from the coronavirus. Marcel Gülicher and Marcel Reinhardt begin by opening the glued unit of a faulty battery with special tools. Every move is perfect. Like all the Center’s employees, they are trained to high-voltage level 5 standard. Only high-voltage experts are allowed to open the units.

Gülicher and Reinhardt gently set down the housing, carefully look at the modules, and the diagnostic work begins. In the simplest case, only a control unit needs to be replaced. “But if, for example, a battery cell at the bottom no longer functions and has to be replaced, then it gets complex,” says the production manager. After all, depending on the battery type, between 200 and 300 battery cells are bundled into 18 to 27 modules.

“In the simplest case, a control unit is replaced. If a cell at the bottom malfunctions, then it gets complex.”

Later, after the repairs are done, the battery is moved to another test stand. Depending on the battery type, six different ones are available. Each unit is tested for its performance and extensive leak tests are carried out. “Only fully functional batteries go back into the truck and to the warehouse as replacement batteries.” So far, hardly any battery units have had to be discarded.

And even if a battery can no longer be used in a vehicle, there are other interesting uses for it, says Grassmuck. At the Dudenhofen Test Center, for example, a container filled with discarded batteries is used as a mobile charging station. He is convinced: “E-mobility is a real plus. I drive a Mokka-e and a Grandland X plug-in hybrid – the driving fun is sensational.” And he knows: if need be, a fast, functioning battery replacement service is ready to help.

May 2021