There are still a dozen pre-production vehicles every day, but the ramp-up phase is not called so for nothing: every day more and more new Opel Grandland models roll off the production line at the Thuringian factory. These are busy weeks for Marc Vockenberg. As manager general assembly and a member of the launch team for the new flagship SUV, he prepares the Eisenach team for production of the new model.

His working days are tightly scheduled with standing on the line, calls and meetings. “It is the typical teething problems that we eliminate in this phase – often in collaboration with the central project teams and suppliers,” says the Thuringian. This fine-tuning of the individual steps and production processes is not new territory for him. The 41-year-old has, among other things, been responsible for the launch of the first Grandland generation. “The fact that we are currently producing both models, the first and second generation, in parallel makes the task even more challenging.”

“The pride of the Eisenach team in being chosen to produce the brand’s flagship SUV is palpable everywhere.”

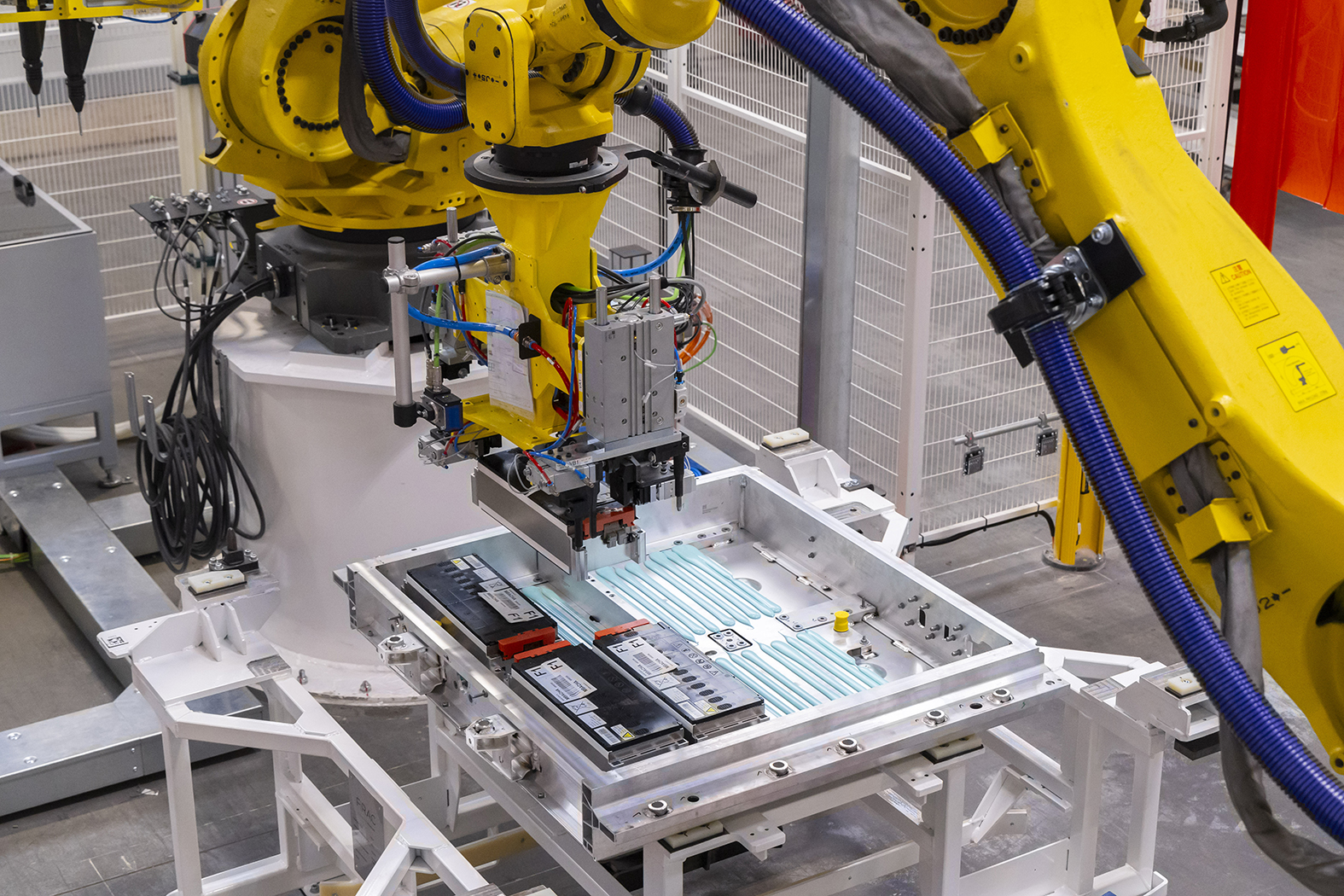

The space to provide the parts on the line is limited. Space is currently a rare commodity in the factory, says Vockenberg. This is also because the factory has positioned itself more broadly for the new model. “The depth of production has increased,” says the manager general assembly. For example, the roof lining and the rear wall flaps are no longer provided by suppliers; they are pre-assembled in the plant. And then of course there is the completely new battery shop.

Eisenach is now an electrical plant

The new Grandland not only rolls off the assembly line with a hybrid drive, but also as battery-electric vehicle for the first time. To be able to manufacture the battery packs directly on site, Eisenach employees have been trained as high-voltage experts. A separate shop was created. The architecture of the BEV-native STLA Medium platform is new, the packaging is particularly flat, and the battery capacity up to 98 kWh. The consequence: the flagship SUV can travel up to around 700 kilometres locally emissions-free.

From the ground up

After a student internship at Opel, Marc Vockenberg began his training as an industrial mechanic with a technical college entrance qualification at the Thuringian factory in 1999. He initially works on the permanent night shift in final assembly, and during the day he completes his mechanical engineering studies. After graduating, he made the leap from production to quality engineering, where he was responsible for the add-on parts for several years. In 2011, as a quality manager, he was given the opportunity to oversee the upcoming ADAM launch. In 2018 he was responsible for the launch of the Grandland X as launch manager. As manager general assembly, he is currently part of the launch team of the new Opel Grandland, which is led by Matthias Bähringer.

“The depth of production has increased

– that’s another reason why currently space is a rare commodity.”

The company invested a total of €130 million to transform Eisenach into an electrical plant. All conveyor systems for the electric SUV were also adapted and strengthened. There is also a second marriage where the chassis, battery and body are brought together. “The installation of the second marriage was an intervention right in the heart of our systems,” says Vockenberg.

Internalize processes on the line

The basic technical requirements have been created. Now it’s time for the colleagues to go through the ramp-up process en route to “saleable vehicles”. Marc Vockenberg himself has worked in final assembly long enough to know what it means when a new model comes onto the line: “We have to work out the peculiarities and special features of the production of the new model. New techniques have to be learned and the changed processes internalised,” he says.

Even after 25 years, Marc Vockenberg still loves the excitement that comes with the launch of a new vehicle. The fascination when the first models leave the factory. Wrapped in camouflage foil as prototypes. “It is these moments that make working in one of the most modern automobile factories in Europe so special.” Now that the first photos of the new Grandland have been published and the world premiere has been celebrated at the factory, a little relaxation is setting in. The camouflage foil disappears and the game of hide-and-seek is over.

High frequency and great quality

The team can devote itselfentirely to the final goal: producing the flagship SUV at high speed and in high quality. Marc Vockenberg can fully rely on his team when it comes to implementation: “The Eisenach team spirit is right – everyone pulls together.” On the one hand, there are the colleagues who have up to 30 years of experience on the line and have immense know-how -how, and on the other hand, the new colleagues who guarantee success with their willingness to go the extra mile. “The pride of the Eisenach team in being able to produce the brand’s flagship SUV is palpable everywhere.”

May 2024