»

The 3D pattern only indicates the contours of the vehicle, blurs them, and confuses onlookers.

Squinting his eyes, Andreas Kubis flinches as each sheet of foil is removed from the vehicle. The 37-year-old’s expression relaxes as the chassis gradually becomes visible. Kubis is a Technical Camouflage Specialist, the trump card in the ongoing battle between Opel and the photographers on the hunt for photographs of prototypes. It’s the reality of his job that makes it hard for him to watch the Astra become exposed. For months he was tasked with rendering the new design language unrecognizable. He camouflaged the newly designed front, disguised the grill featuring the distinctive Opel lightning bolt, and distorted the rear. “It’s difficult to change your mindset from one day to the next,” he says apologetically.

DIFFICULT TIMES FOR CAMOUFLAGE SPECIALISTS

It’s Monday morning. Andreas Kubis has to be particularly brave today. There are another half a dozen Astras in the K40 workshop at the Rüsselsheim factory waiting to reveal their true selves. The first photographs were published a few days ago. The grand deception can be put to an end. Workshop employee Luciano Monaco clearly enjoys removing the privacy shield. The camouflage foil that he strips off is known as ‘Cube.’ Kubis developed it. “The 3D pattern only indicates the contours of the vehicle, blurs them, and confuses onlookers,” explains creator Kubis proudly.

↑ Down to the last detail: A camouflaged wing mirror.

→ After camouflage is before camouflage: Monaco disguises distinctive spots for the post-camouflage process.

CAMOUFLAGE VERSUS RESULTS

If it were up to Kubis, the new Astra would have been completely covered up for the past few months. However, the prototypes can only be distorted to a degree that still allows engineers and test drivers to deliver realistic results for the following production vehicle. Between 70 and 80 sheets of foil are required to completely cover up a vehicle in the compact class. The foil can withstand impacts from small piece of gravel. It can also cope with temperatures ranging from -40°C to +80°C. After all, the test drivers have to be well camouflaged for the freezing conditions in northern Sweden and the sweltering heat of southern Spain.

Isn’t it exhausting always being in competition with prototype photographers? “No, absolutely not,” says Kubis emphatically after taking a moment to think about his answer. It’s this competition that makes things exciting. “Everything associated with development – the pilot production lines, the camouflaged prototypes, the secrecy – that’s what makes working for a car manufacturer so special,” he gushes. The camouflage specialist’s face relaxes. There’s a second reason for that: After workshop employee Monaco uncovers the Astra, he starts to cover up individual parts in what’s known as the post-camouflage process. The Opel lightning bolt on the rear is disguised, and the headlight area and the front end are camouflaged. “The Astra isn’t set to celebrate its world premiere at the IAA Motor Show until September. We need to keep a low profile until then, at least a little bit,” explains Kubis, breathing a sigh of relief.

PERSONAL BIO

There are some jobs that are impossible to aspire to. That’s just the way it is. ‘Technical Camouflage Specialist’ is one of those jobs. Andreas Kubis joined Opel in 1995 as an apprentice industrial mechanic. One of the positions he has held was test system operator in development. After completing the continuing education program to become a technical specialist, he assumed responsibility for global coordination and the transport of prototypes in 2012. At that time, he began creating a camouflage pattern. “If I see a pattern, I take a photo. I work on it on my computer and distort it,” he says, explaining the way he works.

He stresses that teamwork is the most important thing. He works closely with three workshops on the Rüsselsheim premises (PPO General Assembly Test Units, Body/Interior & Aerodynamics Workshops, and PPO Advanced Hardware & Mechanical Workshop). The colleagues specialize in the different areas: camouflaging the exterior, the post-camouflage process, and camouflaging the interior, which is becoming increasingly important. “Working with a top team makes life a lot easier,” adds the camouflage specialist .

The Evolution of Camouflage

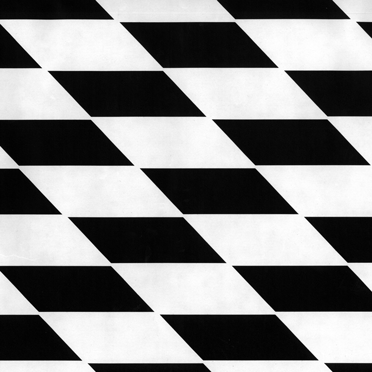

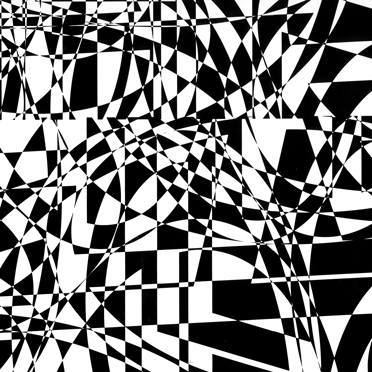

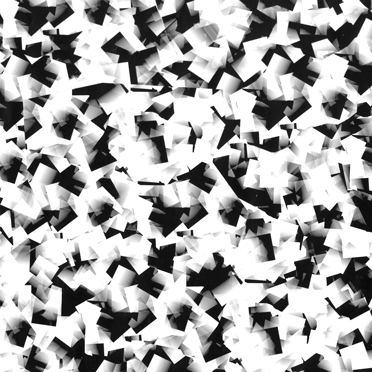

Opel has been designing new camouflage foils for 30 years. The only thing that hasn’t changed is the color combination. It’s always been black and white. It delivers the highest contrast for the human eye and makes it a lot trickier to identify contours.

Fishies, 1999: The first Opel foil camouflage was used on the Corsa C, among other vehicles. A team of up to three people needed several days to apply the foil.

Flimmies, 2009: This pattern was used for the Astra, among others. Each check had to be applied individually. The time required was two days per vehicle.

Wirries, 2011: Screen printing technology was used for the third generation of foils. They could be applied in one piece and saved the experts a day of work.

Cube, 2014: Gray is brought into play alongside black and white. The 3D effects optimally disguise the shape, as can been seen with the new Astra.

Published in June 2015