- Hermann Groß (links) und Hermann Sabotta (rechts) arbeiten seit 1,5 Jahren mit Augmented Reality.

- Mit Hilfe des AR-Systems vergleichen sie das Mockup mit den Konstruktionsdaten.

- Um das System zu kalibrieren, fährt man drei Marker-Punkte an der Karosserie ab.

- Das System arbeitet positionsgenau und in Echtzeit.

- Mit einem Schwenk über den Motorraum wird deutlich, ob alles richtig sitzt.

- Auch GM-Chefin Mary Barra testete während ihres Antrittsbesuchs in Rüsselsheim das AR-Tool.

In a big hall in the International Technical Development Center (ITDC), engine compartment boxes are lined up in a row with various types of engines, so called mockups. Why this variety of test models? With all the electronics and assistance systems, space is tight in the engine compartment. It is the most complex area inside the car apart from the dashboard. The task of Hermann Sabotta and Herman Gross, both engineers, is to utilize the space in the best possible way by applying augmented reality (AR). Hermann Sabotta: “It is getting tighter and tighter in the engine compartment. Thus, even the smallest mistakes effect the result.” Or to stay in soccer image: With the augmented reality tool the engineers of the Vehicle Integration draw “virtual offside lines” into the engine compartment in order to check if everything is in the right spot.

A mockup is the playing field

It takes approximately three months to finish building a physically palpable mockup. During this time, the designers keep working on the virtual model. Before tests can be conducted on the finished mockup, it has to be updated to include the latest design changes. The AR application makes it easier to identify any differences. Gross is convinced about the advantages this technology provides: “The system saves us a lot of time and endless discussions.”

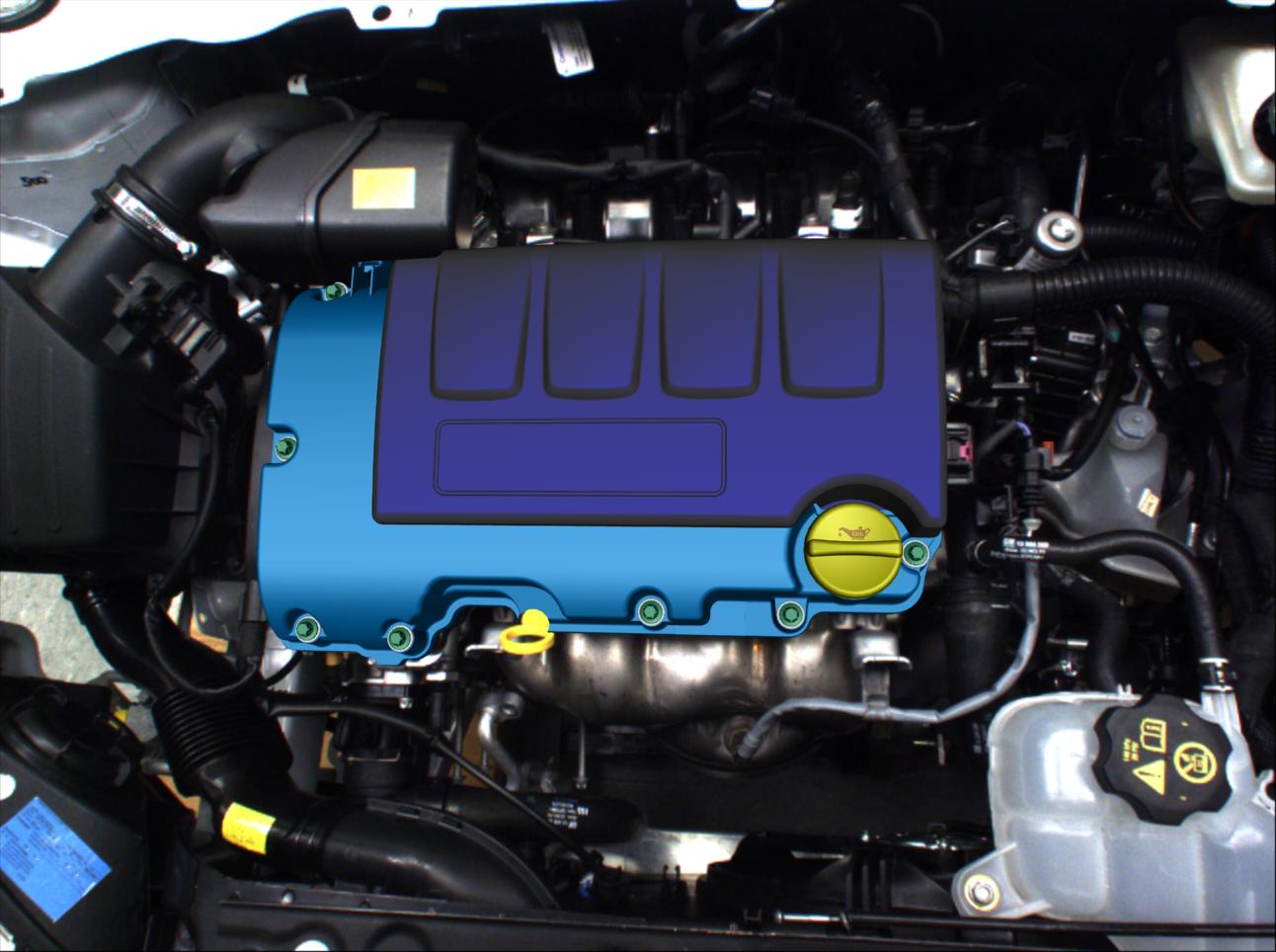

View into an engine compartment with a virtually adapted engine cover.

The AR specialists mainly work together with three partners: internal departments, external engineering firms, and suppliers. If the shape or position of a part is not right, it is often difficult to determine where the problem lies. In many cases, everything looks right and appears to fit perfectly when the components are not yet put together. One look at the screen on which the real image is combined with the digital design data quickly clears up any confusion. But the AR system not only helps to identify problems; it also provides a basis for finding solutions.

Offside? A set of cables being put to the test

By using AR Hermann Sabotta plays the role of a referee. A cable harness in the engine compartment appears to be poorly positioned. Sabotta performs a check with the AR tool. First off he calibrates the program. It uses fixed points marked on the chassis as a reference and tracks the three landmarks. This allows the program to determine which points are on which axes and positions the virtual model accordingly. Then Sabotta scans the engine compartment using the measuring device. The camera transfers the image live onto a large screen. The design data is laid over the real image of the engine compartment in real time.

The areas where the mockup differs from the design data are clearly visible.

The system allows you to overlay either the entire data set or only selected elements. If an area or section is identified that is not consistent with the design data, Sabotta can determine precisely what does not fit by changing the angle. This is a great advantage of this technique, since a cable position might appear correct when viewed from above but is clearly incorrect when viewed from the side. In reality, hoses and cables often do not run as shown in the virtual design, as the material behaves differently or curves along another radius.

Now it’s time to find out what effects or impact the discrepancy will have. Sabotta gives his findings to the designers, who then decide whether the real-life conditions can simply be transferred back to the virtual data. But as soon as there is a problem – for example, a cable is located too close to another component and therefore risks being damaged – the part must be redesigned. Because there is so little space inside the engine compartment, every millimeter counts. Just a few millimeters of overlap could make it necessary to reposition several parts.

The AR hardware and software cost around €100,000. Considering the cost of designing a vehicle, it pays for itself quickly. “The system allows us to avoid costly changes,” says Gross. “It is difficult to put a number on the savings, since the mistakes are not made in the first place. They only occur virtually.” They discover all kinds of things, from small discrepancies such as the position of the bolts to ones that could cause major problems in production. Once mass production is launched, it is difficult and expensive to fix the tools.

Foul or no foul? This ref can explain you even more

But it is not just about finding mistakes or reviewing data. The AR images make it possible to check concepts at an early stage. For example, an Opel model can be equipped with a new bumper in just a few clicks. Rather than generating a static image, the camera can show the object from all sides so that designers can get a good idea of whether the look and mounting concept are suitable and whether the new components fit well with the other parts around them.

The virtual data are overlaid precisely onto the real object.

There is some discussion at Opel about how useful AR really is. Gross and Sabotta provide regular support to other divisions, visiting them with the mobile system. They recently helped their fellow workers in the powertrain department to build a testing system. Sometimes cars are brought over from production to the vehicle integration department for testing if there is something that does not fit.

The possibilities for the future application of AR are tremendous, and not only for development and integration. Augmented reality is also making a difference in other areas such as marketing and service. Soon we will be able to generate new worlds right before our eyes with the use of smartglasses like Google Glass. Until then, we can keep benefiting from it as a virtual referee who always makes the right call.

Text: Sabrina Künz, Photos: Martina Sabais (Asterion)

It consists of a portable coordinate measuring machine, the FaroArm, with a camera attached to it. The two key requirements placed on the system are that it must work with precise positions and in real time. A special program is needed to achieve augmented reality with the measuring system and the camera.

The software was developed by Metaio, a leading global company in the field of augmented reality. In Opel’s case, it was not really love at first sight. As Sabotta recalls, “They presented the system to us, but we weren’t fully convinced. It was not yet adapted to our needs. But I had the feeling it could indeed be of good use.”

Since Opel engineers are curious by nature and always looking for new ways to get better results, they gave the system a chance. Metaio left it with them for a couple of weeks during which they tested it out and discovered potential applications.