- A Northern Irishman in the Adam Opel Haus: Richard Greer is new at the company, “whose products, especially the ADAM, impress me for years”. As “Safety and Industrial Hygiene Senior Manager” Greer wants to intensify the appentence for wellbeing among employees of Opel/Vauxhall. Projects such as the Global Safety Week offer a big stage for his concerns – including “a dash of fun and entertainment,“ says Greer.

Personal details

Richard Greer, born in 1968, grew up in the countryside on a potato farm near Belfast, Northern Ireland. The passionate rugby player and sailor studied mechanical engineering and later worked as a project engineer and quality assurance manager. When Greer was in his twenties he was moved by two fatal accidents, one at work the other at home. A production worker at the company Greer was working for was crushed in a machine; in addition, an acquaintance fell off a ladder while changing a lightbulb at home.

![]()

“Preventable accidents,” says Greer who henceforth concentrates on occupational safety, implementing “Safety Management Systems“ and cultural change for the production and administration areas of large companies. Greer joined Opel/Vauxhall as “Safety and Industrial Hygiene Leader“ in June. He and his team support all European sites.

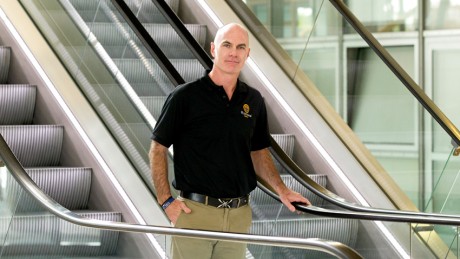

What can we improve? Richard Greer in conversation with Ralph Krust, manager of final assembly and finishing in Rüsselsheim.

It was at sea, somewhere in the Tasman Sea, with a storm raging when Richard Greer realized that he had left his comfort zone. High waves were hitting the deck while Greer was at to bow with team mates, changing a sail on the yacht. “I felt a mix of fear and exhilaration during this moment two years ago,” he says today. “This extreme experience helped me test my willingness to take risks and push my limits.”

FACEOFF WITH DANGER IN THE TASMAN SEA

The fact that this comes from an expert for operational and industrial safety adds a little bit more spice. At least at first. However, Richard Greer is serious about his faceoff with danger. He recalls the race on a 25-meter yacht from Albany to Brisbane (Australia) an “educational adventure that built a feeling of humility in every participant.”

The crewmembers, many of whom did not know each other before, had to pull together, trust each other and come through as a team. “That is generally how things work at a company like Opel/Vauxhall too – and especially when it comes to the principle of operational safety.” It is impossible to wrap employees, suppliers and visitors up in cotton wool and tell them that everything is fine and safe. ”Every leader, team member and employee has a vital role to play and, when each play their role to come through as one team any storm can be weathered.”

FORKLIFT TRUCK AND ESCALATOR DEMAND SPECIAL CAUTION

According to Greer potential health and safety threats are omnipresent at work. That can be a forklift truck colliding with a pedestrian in production. The roof of a building on which a contractor is working without fall protection. It can be an escalator in the administration area that is accessed with hands full and no possibility of a fall being prevented if the person in question stumbles.

![]()

GLOBAL SAFETY WEEK

This week (August 31 to September 4), a global week of occupational safety will take place in all GM business locations to, on the one hand, to celebrate safety as a value but to also remind people how important safety is – both at work and at home.

![]()

![]()

![]()

![]()

Excessive levels of paint fumes or noise are also come into question just like the possibility of people not knowing how to react when the fire alarm rings.

“The principle of continuous improvement applies to safety risks just in the same way it applies to production or any other area of the business. Our challenge is to proactively improve, without the pain of an injury or loss in order to learn“, said Richard Greer. ”Live Values that return people home safely, every person, every site, every day.” This goal is in every business plan and is much more important than any productivity gains.” As his safety philosophy matches the philosophy of Opel/Vauxhall, he joined the company as “Safety and Industrial Hygiene Leader“ in June.

INTERACTIONS WITH OPERATORS AND VP’S

Greer and his team support all of the European business sites. “The exciting thing is that I can move on all levels of the hierarchy.” Greer talks to colleagues on the production line, with safety specialists from the various departments and plants and to the business leaders and VP´s.”

“As soon as each and every person in the company continuously questions existing systems, then we will have succeeded in making health and safety a bit sexy.”

— Richard Greer —

Greer’s strategy? “I want to show that every injury is preventable as long as the people consider safety as an affair of the heart rather than just keeping it in the back of their mind. It needs to be part of the company culture. In practice, this means: not only introducing standardized procedures, not only preaching the GM Safety Management System and values. In addition, the pleasure of well-being needs to be awakened in everybody in the company with personal accountability and self-initiative acting as the engine.

IT TAKES CURIOSITY AND IN A CERTAIN WAY HUMILITY

“As soon as each and every person in the company continuously questions existing systems, as soon as the employees watch out for themselves and others on the way to work or when gardening then we will have succeeded in making health and safety a bit sexy,” said Greer. Initiatives such as Opel Group CEO Dr. Karl-Thomas Neumann working on the production line for a day help pave the way. “Taking an interest in the business and challenges of other people working in the same company is about curiosity and, in a certain way, humility.

»Always behave in a way that does not endanger yourself or others.«

— Richard Greer —

BENEFIT FROM YOGA AND HEALTHY EATING

Awareness for the serious topic can also be raised on the big stage “with a pinch of humor and entertainment”. The Global Safety Week (August 31 to September 4) delivers that stage. Presentations, lectures and workshops at the various business sites provide views from different angles and ideas. According to Greer, campaigns such as “Slips, trips, and falls”, “Safe work at heights” and “”work desk ergonomics” provide the awareness and a consciousness about how to stay safe. And if the organization succeeds in improving the well-being of the employees with offers such as yoga, healthy eating and courses for people trying to quit smoking, “then we are moving in the right direction.”

NEXT MISSION: CROSS THE PACIFIC

During his spare time Greer wants to return to the seas and expose himself to the ultimate danger: race across the pacific from Asia to the west coast of the United States. “Pushing myself with such a risky challenge is not only exhilarating and testing. It is also the best practical training possible with regard to the aspects of protection, safety and health.”

![]()

GLOBAL SAFETY WEEK

![]()

There will also be numerous activities in Rüsselsheim. One of Richard Greer’s personal favourites is “Safety Land”.

The project that has already started successfully in Aspern looks to a practical approach to potential occupational hazards. It is basically a big room for occupational safety. Visitors can for example sit in a forklift truck and experience how lifting devices can impede the sight of a driver. They also learn to work safely with ladders, regarding the selection of the matching device, but also the subsoil.

Through their own initiative, colleagues from Manufacturing Engineering and from Facilities in Rüsselsheim have been inspired to launch their own. “Safety Land”. In future, it is to be established a regular feature in Rüsselsheim.

![]()