Opel Engineer Andreas Liljekvist

“I usually spend the entire winter on test drives, mostly in Lapland,” says Opel Engineer Andreas Liljekvist as he sits at his desk in the ITEZ in Rüsselsheim, Germany at the end of February. There are only a few items on said desk, but they reveal a great deal about him. He’s placed the clutches for the first- and second-generation Insignias on the left-hand side, and plastered the wall across from the desk with a XXL calendar on which he has marked out long trips to places such as Trollhättan, Arjeplog, and Corvara. “The test drives for the Insignia four-wheel drive systems were held in northern Sweden and the snowy Alps,” says Liljekvist, explaining the calendar entries. One of his computer screens is filled with colorful, overlapping graphs. Meanwhile, photos next to the second monitor speak to Andreas’ private life: snapshots of his hometown in Sweden, motocross races, and his family.

Liljekvist: “We carry out most of the tests on snow because it’s the most challenging surface to drive the car on.”

Off on a test drive in Sweden …

… and another one in Australia.

Liljekvist has been working at Opel as a development engineer since 2010. The 40-year-old tests four-wheel drive and chassis control systems until they work perfectly and are ready for series production. Opel currently offers four-wheel drives in the Mokka X and the Insignia. The new flagship vehicle also features a FlexRide chassis with active shock absorbers, and is the first Opel on the market to feature a Twinster four-wheel drive including torque vectoring – tested and co-developed by Liljekvist himself. The motorsports fan and trained vehicle technician spends roughly half of his time working on testing tracks. He covers hundreds of thousands of kilometers each year on various different surfaces: ice, snow, gravel, sand, and asphalt.

At work behind the steering wheel

“We carry out most of the tests on snow because it’s the most challenging surface to drive the car on. These test drives are particularly important for 4×4 systems,” explains Liljekvist. He adds that today is somewhat of an exception – he wouldn’t normally be in Rüsselsheim. “Between the beginning of December and the end of March, I’m at test drives almost the entire time. Otherwise, I’m planning and analyzing the tests, or I’m out on gravel and asphalt tracks.”

Fine-tuning in the Opel Test Center in Dudenhofen: Liljekvist checks out, among other things, the different chassis and drive settings (Standard, Tour, and Sport) for the Insignia Grand Sport.

Before Liljekvist can carry out analyses, the cars and prototypes need to be fitted with measurement systems to record the force exerted on the drive shaft, for instance. “The measurement data on the revolutions per minute, the torque, and signals from the chassis control systems are then displayed here in the graphs,” explains Liljekvist, pointing to his screen. “That way, I can see whether, when, and how the car follows my commands. When does the ABS set in? How well does the whole four-wheel drive work? How much traction do the individual wheels have?”

Endless test cycles

The test cycles are endless: Liljekvist fine-tunes, tests, and analyzes the new systems to ensure that they work properly up to their absolute limits. “When an error or a malfunction occurs, we need to immediately retune or replace the software,” Liljekvist explains further. “That’s why we usually carry out each test for several weeks at the same location.”

How much traction do the individual wheels have on the asphalt? The extreme stresses in Dudenhofen provide answers to these kinds of questions.

Round by round: Andreas Liljekvist in action.

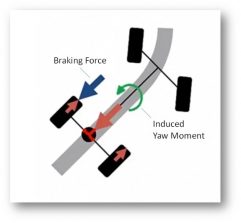

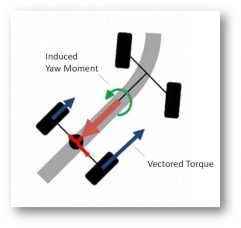

Torque Vectoring

The new Insignia is getting a Twinster four-wheel drive with integrated torque vectoring – two multi-plate clutches on the rear axle replace the conventional differential. This causes the drive power to be individually distributed across both rear wheels within milliseconds. Distributing the gathering drive torque between the individual wheels in this manner ensures ideal traction and acceleration and prevents a drop in performance for the wheel that is turning. Usually, the greater proportion of the power goes to the wheel on the outside of the curve so that the vehicle stabilizes itself. The Insignia also leans more precisely into the curve and responds to driving commands more directly.

Feeling good on the road

The Scandinavian’s key to success sounds both simple and complicated: “You always need to feel good on the road. I want to be able to feel in my body that the car is driving the way I want it to. To make that possible, I need to know in advance how we want to fine-tune the car: For example, how much torque vectoring do we want, and how much torque? Do we want a sporty or a neutral driving style? What’s the Opel philosophy?” asks Liljekvist. He lets his gaze drift out of the window, and provides an answer two beats later: “There are many different options. But we don’t give our approval until the tuning is perfect.” Liljekvist shows in the video what it looks like when “the tuning is perfect” and the torque vectoring is in full swing.

In the video: what perfect tuning looks like

“The Twinster drive system distributes up to 60 percent of the power to the rear wheels and provides the Insignia with better traction and more grip when navigating curves. This four-wheel drive is unique in the Insignia segment, and we’re very proud of that.”

– Andreas Liljekvist –

At the workplace in the ITEZ: Here you can find tools that reveal a lot about Opel Engineer Andreas Liljekvist. These include clutches from the first and second generations of the Insignia, family photos, and a travel route for tests with the new flagship.

Exploring limits in motocross as well: Andreas Liljekvist on his Yamaha YZF 250.

Liljekvist was practically born into his passions for meticulous fine-tuning, high speeds, and testing out boundaries. “My dad started taking me to motocross when I was three years old. A little while later I got my own bike, and I always tinkered around with it after school. I practically grew up in the garage,” says Liljekvist with a grin.

Grew up in the garage

The Swede still likes to ride his bike today – he’s got a Yamaha YZF 250. “When I can make time for it, I ride once a week. Sometimes in Sweden, but usually in the region around here. There’s a few good tracks out here in Germany, too,” says Liljekvist, pointing to a map that he’s marked with nearby motocross tracks. He feels very much at home in his new country, where he has spent seven years so far: “I love Germany just as much as Sweden. The two countries are very similar; they’re not that far apart, after all. There is one big difference, though: The weather in Germany is much better.”

After work in Scandinavia: The new Insignia was tested until sundown.

Last update April 2017